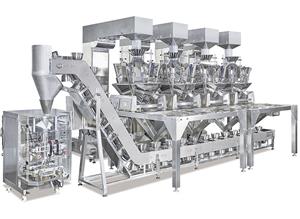

pre made zipper pouch powder rotary doy pack machine with screw filling

- FRONTECH

- CHINA

- 30 days

- 50 set/month

pre made zipper pouch powder mini doypack machine can put powder products into the prefabricated bag, suitable for various powder.Such as milk powder, flour, coffee powder, chili powder, spice powder, soap powder, curry powder, washing powder, garlic powder, onion powder, protein powder, seasoning powder, corn powder, coconut powder etc.

Application

pre made zipper pouch powder mini doypack machine can put powder products into the prefabricated bag, suitable for various powder.Such as milk powder, flour, coffee powder, chili powder, spice powder, soap powder, curry powder, washing powder, garlic powder, onion powder, protein powder, seasoning powder, corn powder, coconut powder etc.

Parameters

| Model | FT-R200 | FT-R250 |

| Packing material | 3-side, four edge-sealing bag, self-reliance bag, handbag, spout bags, zipper bag, compound bag, etc | |

| size | W:70-200 | 100-250 |

| Filling range | 10-1000g | 20-2500g |

| Packing speed | 40-60bag/min(speed is depends on the product natures) | |

| Average precision | ≤ ±1% | |

| Total power | 2.5KW | |

| Dimensions | 1900mm X 1570mm X 1700mm(L*W*H) | 1900mm X 1570mm X 1700mm(L*W*H) |

| Work steps | giving bag→coding →opening →filling 1 →filling 2→ auxiliary→ exhaust→heat sealing→ .forming and output product | |

Features

With different kind of dosing system, capable of packing a wide range of products.

Capable of working with a range of pouches.

Easy to operate, With PLC controller, HMI system makes easy operation.

Easy to adjust bag size on the screen, then the machine will do the adjustment accordingly

High automation, automatic feeding, bag picking, filling, closing, sealing, date coding.

Perfect prevention system: when the bag is not opened or not opened completely, it will be non-filling and non-sealing, so the bags can be reused and the product is not wasted thus save the production cost.

The product contact parts are made of food grad SUS304 to ensure sanitation and safety.

High quality plastic bearings, no need to oil, no contamination.

Vacuum generator, low consumption, high efficiency, cleaness, and long useful life.

Sample bags